PROCESS AND SEPARATE

COMPLEX FLUID MIXTURES.

VAPOR PERMEATION, VACUUM

MEMBRANE DISTILLATION SYSTEMS

& MORE.

AS A ZERO-LIQUID DISCHARGE

SOLUTIONS.

SOLUTIONS FOR CHALLENGING

PROCESS NEEDS.

Petro Sep is pioneering membrane-based systems for complex separation needs since 1999.

![]()

Clean Technology Solution for the World

TECHNOLOGIES

Technology Overview

For over 20 years, Petro Sep has developed world-leading membrane-based patented systems, such as AQUA-SEP®, VOC-SEP®, AZEO-SEP®, as well as proprietary processes and domain expertise for complex fluid separation problems.

Patents & Processes

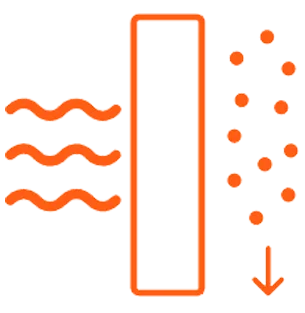

Vacuum Membrane

Distillation (VMD)

AQUA-SEP® can recover up to 99.99% of water from wastewater

Pervaporation (PV)

& Vapor Permeation (VP)

AZEO-SEP® & VOC-SEP® to recover VOC’s or Azeotropes

Hybrid Systems

Our Systems Supplement Desalination Plants to Treat RO Reject Brine

World-leading authority on cutting edge technology! Explore our products.

Product Features

Custom & Novel Applications

High Selectivity & Purity

Unique Azeotropic Mixture Separations

Low Footprint

Short Payback Period

INDUSTRIES

Industry Overview

Industries today are constantly striving to optimize procurement and extraction of input (upstream) resources, management of midstream processes as well as disposal of end of cycle output (downstream) waste.

Our Industries

Our solutions integrate with existing plants and provide a hybrid solution with a small footprint.

SERVICES

Service Overview

Petro Sep is a recognized industry leader in vacuum membrane distillation (VMD), pervaporation (PV) and vapor permeation (VP) technologies to solve complex fluids separation problems at an industrial scale that are also economical and environmentally sustainable.

Turnkey solutions that will save you money and help the planet.

Get in Touch

You will find yourself working in

a true partnership with results.